- info@agrolytix.com

- +49 9131 8529452

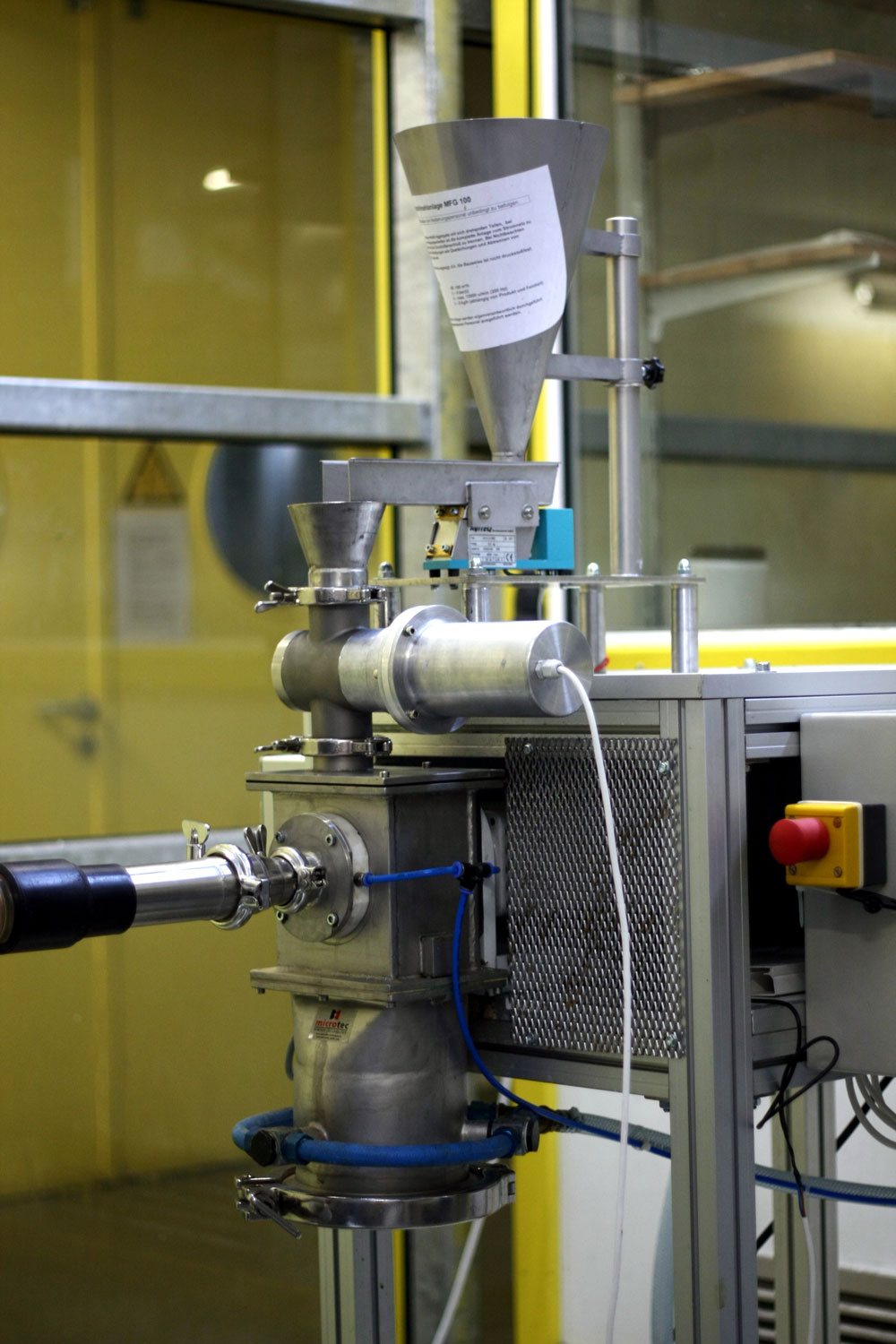

Micronizing in toll manufacturing

By means of a modern fluidized bed opposed jet mill, we grind your coarse materials to particle sizes between 5 µm to 100 µm. The use of purified compressed air, respectively nitrogen as inert grinding air, accelerates the particles to such a degree that they collide with increased speed and in this way comminute each other. The fine grinding occurs without notable erosion of the grinding tools, which is why this grinding method is especially suitable for the efficient milling of very solid materials, as it works nearly contamination-free. An air separator integrated in the jet mill allows for the exact regulation of a desired particle size spectrum. The order quantities range from few grams to many kilograms.

Cosmetics Industry:

Application areas and examples

Agricultural Chemistry:

- Micronizing of solid agricultural chemicals to fine powders, e.g. for an improved spray deposit on the leaf surface

- Grinding of copper salts as biological fungicides with improved release kinetics

- Milling of biologically active ingredients for the production of wettable powders or water dispersible granules

- Micronizing solid agents for a subsequent microencapsulation

Cosmetics Industry:

- Increased surface-volume-ratio of micronized agents and additives in cosmetic products lead to more stable dispersions

- Change in viscosity, for example of creams or pastes

- Reduced perception of micronized particles on the skin